With the continuous development of the construction industry, the new concept of green construction has been paid more and more attention by the construction companies,especially in the temporary construction industry, the market share of the prefabricated house(light steel movable plank building) is more less, while more market share is occupied by of modular house ( flat-packed container house)

Under the trend of vigorously developing the construction industrialization, the removable and redetachable modular house will replace the light steel movable plank building!

Reason?? Let's analyze it through the following comparison!

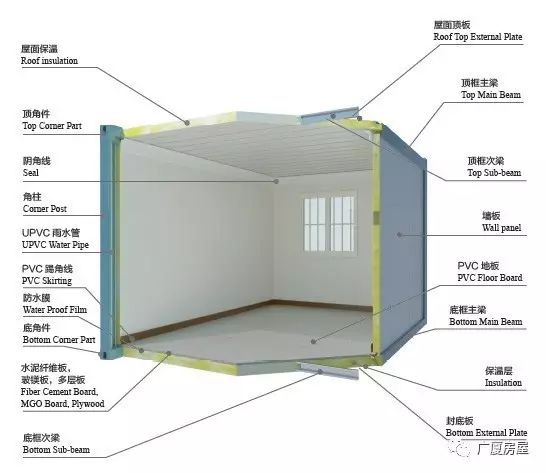

1. Structural comparison

Flat packed container house - New eco-friendly building: the house is composed of structural system, ground system, floor system, wall system and roof system, use one standard house as the basic unit. the house can be combined horizontally or vertically in various forms.

The house’s systems are prefabricated in factory, and assemble on site.

The light steel movable plank building is inlaid structure with small resistance, it is easy to collapse in case of unstable foundation, typhoon, earthquake, etc.

2. Design comparison

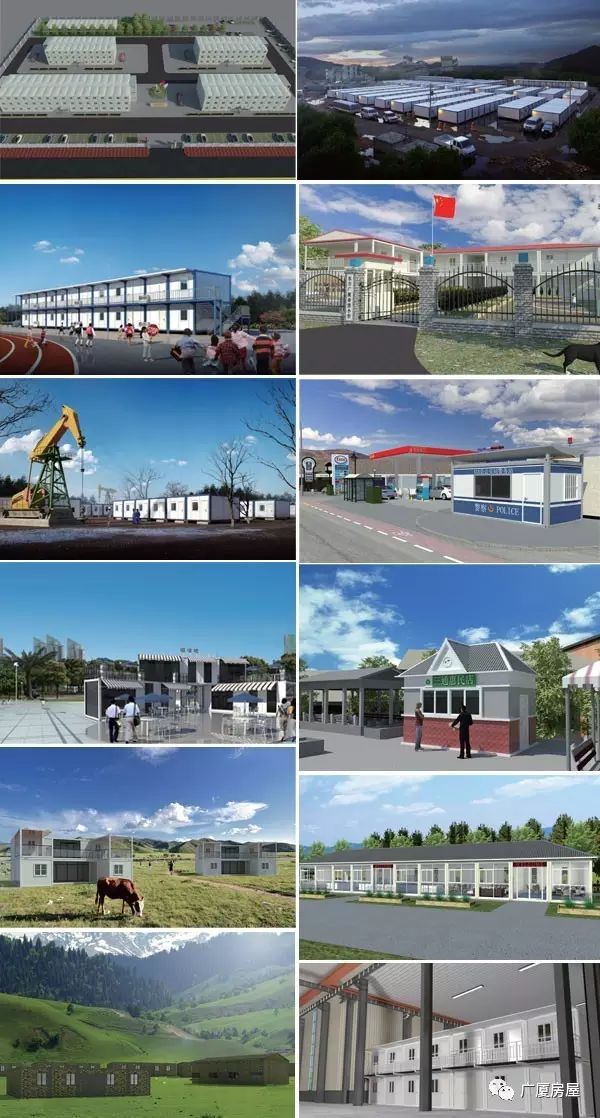

The design of flat-packed container house introduces modern household elements, which can be assembled and disassembled freely according to the different environment and demand of the house. According to the changes of the environment, users can choose the assembly mode of each module to create a personalized house. The adjustable housing base can also adapt to the requirements of different floors. The exterior of the house can also be attached with other building decoration materials as envelope and surface decoration or decoration.

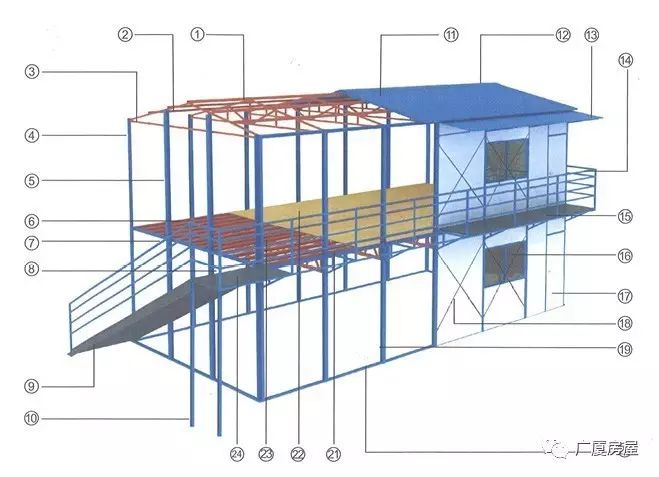

The flat-packed container house takes a single house as a unit, and can be stacked and combined arbitrarily within three layers, modeling roof, terrace and other decorations can be added.

The design of light steel movable plank building is based on steel, plate and other raw materials for on-site installation. The performance of sealing, sound insulation, fire prevention, moisture-proof and heat insulation is poor.

3. Performance comparison

The seismic resistance of flat-packed container house: 8, wind resistance:12, service life : 20+ years. High quality, Eco-friendly, recycled material is used on the modular house, The wall is made of all cotton plug-in color steel composite plate without cold bridge. The components are connected with non cold bridge. Cold bridge will not appear due to core shrinkage when subjected to vibration and impact, so as to avoid cold bridge on the upper part of the component after the shock of bulk insulation materials. The rock wool strips can keep good heat preservation and heat insulation performance in high temperature or low temperature environment, which has the characteristics of non burning, non-toxic, light weight, low thermal conductivity, sound absorption performance, insulation, chemical stability, long service life, etc. The modular house is more sealed, soundproof, more fireproof, more moisture-proof and more heat insulation than the traditional light steel movable house.

The light steel house: Grade 7 earthquake resistance, grade 9 wind resistance. service life: 8 years, it can be disassembled 2-3 times. The performance of fire prevention, moisture-proof, sound insulation and heat preservation is poor.

4.Foundation comparison

The foundation of flat packed modular house is more simpler, which can be made into strip foundation or pier foundation, or even can be placed directly on the ground without foundation, and the indoor ground does not need to be leveled too.

The foundation of light steel house is troublesome. The concrete foundation is poured with 300 mm x 300 mm. The house is connected with the foundation by expansion bolts. The ground of the first floor of the house needs to be leveled with concrete. After the house is moved, the foundation can not be used again

5. Installation comparison

The flat packed modular house is installed quickly, so construction time is short, one single modular hose can be finished the installment by 4 workers in 3 hours; It can also be transported in full containers , then the house can be used after connecting the water and electricity on site.

The light steel house needs to pour the concrete foundation, to do the main body, install color steel plate,suspend the ceiling, install water and electricity etc. the construction time is long with a period of 20-30 days, and there is high risk of operation and labor loss.

6. Transport comparison

The modular house can be disassembled into plate packing, which is suitable for sea and land transportation.

Land transportation: the 17.4M flat car can hold 12 sets, which greatly saves the transportation cost.

In short distance, the house can be prefabricated and assembled in the factory, transported to the site in a whole box, and directly used after hoisting.

Sea shipping: usually 6 sets in a 40HC.

The light steel house: the material is scattered and the transportation is troublesome.

7. Comparison of application

The modular house can be used in engineering camp, logistics park, military, municipal, commercial, oil field mining, tourism, exhibition, etc. it can be used for living, office, storage, commercial operation, tourism landscape, etc. it can improve the comfort and meet the needs of life.

The light steel house: basically only used for temporary construction sites.

8.Comparison of energy conservation and eco-friendly

The modular house adopts the mode of "factory manufacturing + on-site installation", and the construction site does not produce construction waste. After the demolition of the project, there will be no construction waste and no damage to the original environment. The house can be recycled use with zero loss in transition and reducing environmental pressure.

The light steel house: on site installment will cause damage to the resident environment, and there are a lot of construction waste and low recycling rate.

Manufacture of packing house

Each set of the container house adopts modular design, factory prefabrication production. Taking one house as the basic unit, it can be used alone or combined through different combinations to form a spacious space. The vertical direction can be stacked up to three floors. Its main structure is made of high-quality steel customized standard components,the anti-corrosion and anti rust performance is superior, the houses are connected by bolts. It’s simple structure, quickly installation and other advantages, has been gradually recognized by people, modular houses will also lead the development trend of the temporary construction industry.

With the continuous changes of the market, Beijing GS Housing Co., Ltd. (hereinafter referred to as GS Housing) is also constantly adjusting our development strategy, improving the manufacturing technology, upgrading and transforming its production equipment, introducing high-quality talents, focusing on R & D, manufacturing and sales of modular house, so as to provide the high-quality modular house with good safety performance to society.

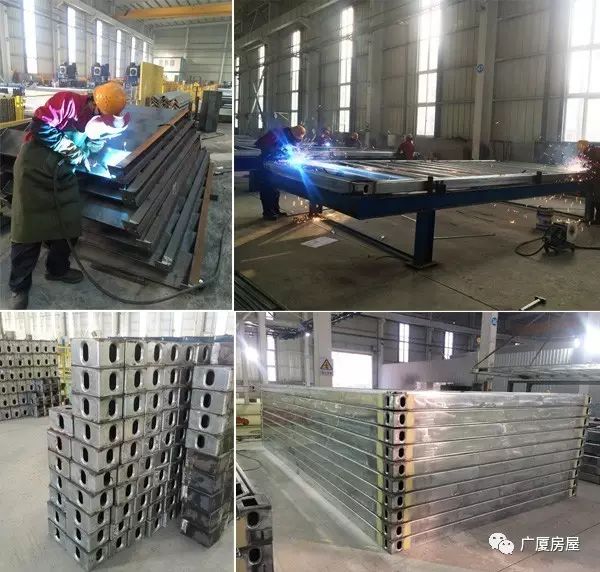

Component welding

The components of our modular house are welded and manufactured by our own factory. Strictly control the quality.

Grinding, galvanizing and coloring

the anti-corrosion and anti rust performance is superior because the surface of the standard components produced is polished and galvanized, the color of the modular house can be customized according to customer's requirements.

Assembly

The modular house can be prefabricated in the factory. It can be shipped to the project site after assembled the waterways, circuits, lighting and other facilities into the finished products in the factory, then connect the water and electricity with the site facilities.

Post time: 30-07-21