Why Modular Container Kitchens Are Taking Over Every Tough Job Site

Projects get bigger, and Porta Camps get more remote.

Flat-pack containers turned out to be the perfect building block—not too heavy to ship, not too costly to customize, and roomy enough for all the stuff that makes a kitchen actually work: air ducts, grease extraction, and separate prep and wash zones.

You’ll find them in all temporary living situations:

Mining base camps where the nearest town is 100 km away

Construction sites that wrap in one year or 10 years

Stadium parking lots turned pop-up catering hubs for championship weekends

Schools and hospitals are using them during renovations

Military field ops where chow has to be hot and on time

Disaster zones, where a hot meal is as critical as a first-aid kit

Wherever people gather to work, modular kitchens follow.

What Is a Modular Container Kitchen?

It’s a commercial-grade container kitchen, built in a factory, shipped flat, and assembled on-site in days.

A container kitchen is not a beat-up shipping container with a stove bolted to the floor. It’s engineered from the ground up for food safety first: controlled airflow to keep grease from building up, non-porous food-grade surfaces that wipe clean in minutes, commercial grease traps, HACCP-friendly layouts, and electrical systems that pass EU and US certifications without breaking a sweat.

Traditional build method? slow, expensive, and stuck in one spot forever.

Converted containers? Sturdy, sure—but no ventilation, no proper zoning, and one inspection away from getting shut down.

Flat-pack modular kitchens hit the sweet spot: fast, flexible, sanitary, and tough as nails.

You get order, not chaos: Prep → Cook → Serve → Wash—clean, separate zones that health inspectors love to see. Alternatively, you can create separate hot and cold kitchens if required by your local regulations.

|

|

5 Non-Negotiable Wins of Modular Kitchen Solutions

1. Speed You Can Plan On: Operational in Days

A full catering lineup and running in a week—max. Small setups can be ready in as little as one day.

2. Hygiene Engineered In, Not Added On

Built with food-grade panels that resist bacteria, featuring seamless surfaces with no cracks for grime to hide. It’s designed to pass inspections from day one, eliminating the risk of costly shutdowns.

3. Mobility as a Standard Feature

The prefabricated canteen’s core design principle is relocation. Pack it up, lift it with a crane, and redeploy it to your next site. This transforms your kitchen from a sunk cost into a reusable, movable asset, cutting long-term project expenses.

4. Scalability That Grows With Demand

Start with a cook pod. A bakery module, a cold room, a dedicated dish station, or a buffet hall can be added according to your demands.

5. Built for Environmental Assault

The container canteen is engineered to thrive in desert heat, coastal salt spray, rain-forest monsoons, and alpine snow. The performance doesn’t dip with the temperature or humidity, ensuring consistent operation.

|

|

Case Study: Feeding Thousands in Indonesia’s Morowali Mining Camp

Aerial photo showing the expansive GS Housing mine camp at the Morowali Industrial Park, with multiple container kitchens, worker dormitory, and dining hall units neatly arranged.

This was Morowali—one of the hottest, wettest, and most remote mining camps in Southeast Asia. The client needed to feed thousands of workers, round the clock, on shift cycles that ran day, night, and everything in between.

The GS Housing system for modular worker housing was deployed at an incredible speed. Explore the full scope of this landmark project on our case study page: Indonesia Morowali Industrial Park Mining Camp→

The temporary kitchen building complex was just one part of a full man camp solution that included 1,605 living container units, dedicated sanitation modular houses, and container dining halls.

Engineering for the Extreme: The Specs That Made It Work

Here’s how we engineered a portable container kitchen to withstand Morowali:

Fire & Structure:

Wall panels with ASTM-tested 1-hour fire resistance. A frame built with 0.5 mm galvanized steel (zinc coating ≥40 g/㎡) for maximum corrosion defense.

Advanced Protection:

Graphene powder coating for 20-year anti-rust and anti-fade protection, even in salt-air humidity.

Climate-Proof Insulation:

Hydrophobic rock wool insulation—A-grade non-combustible, preventing mold growth in constant monsoon humidity.

Sanitary Interior:

0.5 mm aluminum-zinc coated interior plates with a PE finish—creating a smooth, scrubbable, and sanitizer-resistant surface.

Water Management:

A 50 mm PVC drainage stack at every module corner and a 360° overlap roof ensured storm-water was efficiently shed, keeping the interior dry during torrential rains.

Triple-Layer Sealing:

Butyl tape, sealing strips, and an S-joint wall latch system effectively locked out dust, pests, and moisture.

“We thought we’d have to shut down for a week during the worst of the rain,” was the modular bunkhouse camp manager’s feedback. But the temporary catering kitchen just kept going. Workers got hot meals, on time, every single shift. That’s the difference between a ‘container with a stove’ and a real kitchen.”

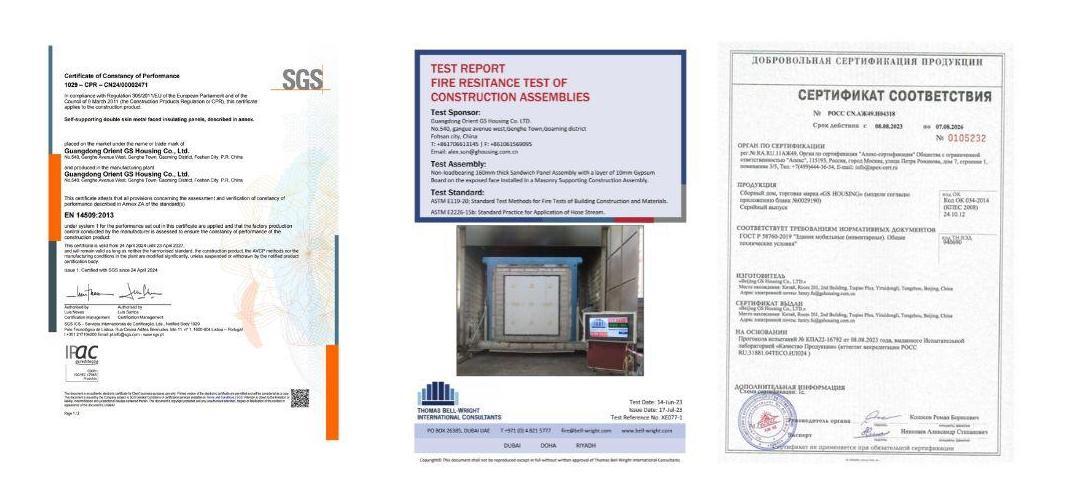

Global Compliance & Electrical Systems: Pre-Certified for Peace of Mind

Different countries, different plugs, different rules—we get it. As a leader in modular kitchen factories in China, GS Housing ensures compliance is baked in, not bolted on.

CE is certified for the European Union.

UL listed for the United States and Canada.

EAC compliant for Russia and the CIS nations.

Full electrical adaptation to your region’s voltage and circuit codes during factory production.

Your modular kitchen system arrives as a complete, turnkey system. For a complete view of our global capabilities and projects, visit our homepage at www.gshousinggroup.com.

Who Needs This Kitchen? (If You Hate Delays, It’s You)

If you’re feeding people who don’t have time for construction delays—this is for you:

Resource Sector: Mining, oil, and gas teams in remote locations.

Fast-Paced Construction: Seasonal or per-project crews that relocate.

Major Events: These include festivals, sports games, or exhibitions that require mobile kitchen building.

Critical Infrastructure: Temporary medical camps and field hospitals where hygiene is non-negotiable.

Defense & Aid: Military field operations and humanitarian relief forces.

Tents and gas burners only get you so far. This is the next tier—the prefabricated modular kitchen that keeps your project alive, your team fed, and your timeline intact.

|

|

FAQ

Q1: How long from order to the first meal served?

A: Different country, different shipping time, but typically 3–10 days after container modules arrive on site. Small detachable modular kitchens can be ready in 1 day; large kitchens take up to 10 days.

Q2: Can the modular kitchen handle heavy daily use and cleaning?

A: Absolutely. The container kitchen building is built like a permanent commercial kitchen. Standard features include industrial grease extraction, washable sanitary surfaces, and anti-slip flooring designed for high-pressure daily cleaning.

Q3: Is it really expandable after the initial setup?

A: Yes. The flat-pack modular design is meant for expand. You can add or reconfigure modular units later, protecting your initial investment.

Q4: How does it hold up in corrosive coastal or tropical environments?

A: The combination of graphene coating, hot-dip galvanized steel, and enclosed drainage systems is specifically engineered for these environments, offering a design life of 20+ years.

The Modular Kitchen That Enables Everything Else

The Modular Kitchen That Enables Everything Else

A GS Housing modular container kitchen keeps your projects alive, morale high, and operations on schedule.

In remote dust fields, sweltering industrial parks, cyclone-battered coasts, or temporary event sites—it’s the one system that delivers relentless reliability.

Post time: 15-12-25