At present, most people pay attention to the carbon reduction of buildings on permanent buildings. There are not many researches on carbon reduction measures for temporary buildings on construction sites. Project departments on construction sites with a service life of less than 5 years generally use reusable modular-type houses, which can be reused. Reduce the waste of building materials and reduce carbon emissions.

In order to further reduce carbon emissions, this filedevelops a turnable modular photovoltaic system for the turnaround modular house project to provide clean energy during its operation. The same turnaround photovoltaic system is arranged on the temporary building of the project department of the construction site, and the standardized photovoltaic support and its photovoltaic system design are carried out in a modular way, and the modularized integrated design is carried out with a certain specification of unit modulus to form an integrated and modularized, detachable and turnable technical products. This product improves the power consumption efficiency of the project department through "solar storage direct flexible technology", reduces carbon emissions during the operation of temporary buildings on the construction site, and provides technical support for the realization of the goal of near-zero carbon buildings.

Distributed energy is an energy supply method that integrates energy production and consumption arranged on the user side, which reduces the loss during energy transmission. Buildings, as the main body of energy consumption, use idle rooftop photovoltaic power generation energy to realize self-consumption, which can promote the development of distributed energy storage and respond to the national double carbon target and the 14th Five-Year Plan proposal. The self-consumption of building energy can improve the role of the building industry in the country's dual carbon targets.

This file studies the self-consumption effect of temporary building photovoltaic power generation in construction sites, and explores the carbon reduction effect of modular photovoltaic technology. This study mainly focuses on the project department of modular-type houses on the construction site. On the one hand, because the construction site is a temporary building, it is easy to be ignored in the design process. The energy consumption per unit area of temporary buildings is usually high. After the design is optimized, carbon emissions can be effectively reduced. On the other hand, temporary buildings and modular photovoltaic facilities can be recycled. In addition to photovoltaic power generation to reduce carbon emissions, the reuse of building materials also greatly reduces carbon emissions.

"Solar storage, direct flexibility" technology is an important technical means and effective way to achieve carbon neutrality in buildings

At present, China is actively adjusting energy structure and promoting low-carbon development. In September 2020, President Xi Jinping proposed a dual-carbon goal at the 75th session of the United Nations General Assembly. China will peak its carbon dioxide emissions by 2030 and achieve carbon neutrality by 2060. "The Suggestions of the Central Committee of the Communist Party of China on Formulating the Fourteenth Five-Year Plan for National Economic and Social Development and the Long-term Goals for 2035" pointed out that it is necessary to promote the energy revolution, improve the capacity of new energy consumption and storage; accelerate the promotion of low-carbon development , develop green buildings and reduce carbon emission intensity. Focusing on the dual carbon goals of carbon neutrality and the recommendations of the 14th Five-Year Plan, various national ministries and commissions have successively introduced specific promotion policies, among which distributed energy and distributed energy storage are the key development directions.

According to statistics, carbon emissions from building operations account for 22% of the country's total carbon emissions. The energy consumption per unit area of public buildings has increased with the construction of large-scale and large-scale centralized system buildings newly built in cities in recent years. Therefore, the carbon neutrality of buildings is an important part of the country to achieve carbon neutrality. One of the key directions of the construction industry in response to the national carbon neutral strategy is to build a new electrical system of "'photovoltaic + two-way charging + DC + flexible control' (photovoltaic storage direct flexible)" under the situation of comprehensive electrification of energy consumption in the construction industry . It is estimated that the "solar-storage direct flexible" technology can reduce carbon emissions by about 25% in building operations. Therefore, the "solar-storage direct-flexibility" technology is a key technology to stabilize power grid fluctuations in the building field, access a large proportion of renewable energy, and improve the electrical efficiency of future buildings. It is an important technical means and effective way to achieve carbon neutrality in buildings.

Modular Photovoltaic System

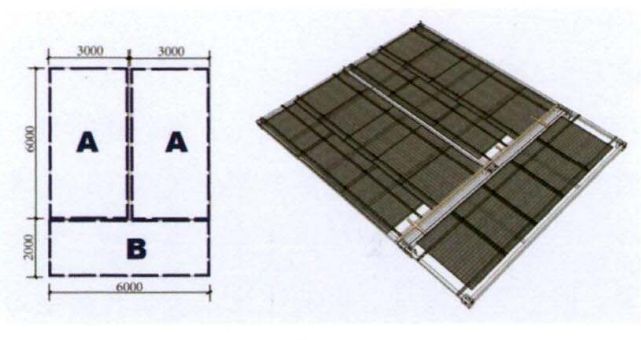

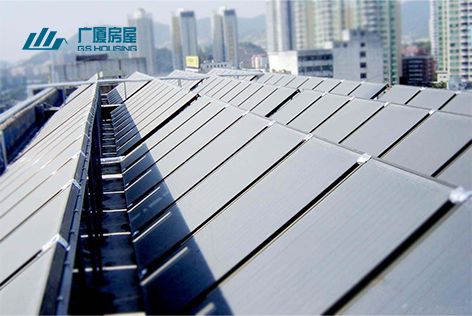

The temporary buildings on the construction site mostly use reusable modular-type houses, so a modular photovoltaic module system that can also be turned around is designed for the modular-type houses. This zero-carbon site photovoltaic temporary construction product uses modularization to design standardized photovoltaic supports and photovoltaic systems. First, it is based on two specifications: standard house (6×3×3) and walkway house(6×2×3) , photovoltaic layout is carried out in a tiled manner on the top of the modular-type house, and monocrystalline silicon photovoltaic panels are laid on each standard container. The photovoltaic is laid on the photovoltaic support below to form an integrated modular photovoltaic component, which is hoisted as a whole to facilitate transportation and turnover.

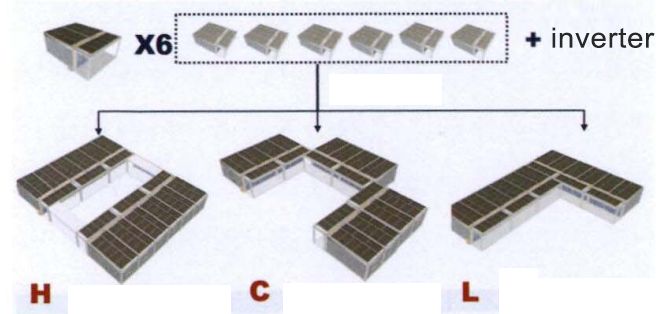

The photovoltaic power generation system is mainly composed of photovoltaic modules, inverter control integrated machine, and battery pack. The product group consists of two standard house and one aisle house to form a unit block , and six unit blocks are combined into different project department space units, so as to adapt to the spatial layout of the project department and form Prefabricated zero-carbon project plan. Modular products can be varied and freely adapted to specific projects and sites, and use BIPV technology to further reduce the carbon emissions of the overall building energy system of the project department, providing a possibility for public buildings in different regions and under different climates to achieve carbon neutral goals. The technical route for reference.

1. Modular design

Modular integrated design is carried out with unit modules of 6m×3m and 6m×2m to realize convenient turnover and transportation. Guarantee fast product landing, stable operation, low operating cost, and reduce on-site construction time. The modular design realizes the prefabrication of the assembled factory, the overall stacking and transportation, hoisting and locking connection, which improves efficiency, simplifies the construction process, shortens the construction period, and minimizes the impact on the construction site.

Main modular technologies:

(1) The corner fittings consistent with the modular-type house are convenient for the connection of the modular photovoltaic support with the modular-type house below;

(2) The photovoltaic layout avoids the space above the corner fittings, so that the photovoltaic brackets can be stacked together for transportation;

(3) Modular bridge frame, which is convenient for the standardized layout of photovoltaic cables;

(4) 2A+B modular combination facilitates standardized production and reduces customized components;

(5) Six 2A+B modules are combined into a small unit with a small inverter, and two small units are combined into a large unit with a larger inverter.

2. Low-carbon design

Based on zero-carbon technology, this research designs zero-carbon site photovoltaic temporary construction products, modular design, standardized production, integrated photovoltaic system, and supporting modular transformation and energy storage equipment, including photovoltaic modules and inverter modules , battery modules to form a photovoltaic system that realizes zero carbon emissions during the operation of the construction site project department. Photovoltaic modules, inverter modules, and battery modules can be disassembled, combined, and turned over, which is convenient for turning over projects together with the box-type house. Modular products can adapt to the needs of different scales through quantity changes. This detachable, combinable, and unit module design idea can improve production efficiency, reduce carbon emissions, and promote the realization of carbon neutral goals.

3. Photovoltaic power generation system design

The photovoltaic power generation system is mainly composed of photovoltaic modules, inverter control integrated machine, and battery pack. The PV of the modular-type house is laid out in a tiled manner on the roof. Each standard container is laid with 8 pieces of monocrystalline silicon photovoltaic panels with a size of 1924×1038×35mm, and each aisle container is laid with 5 pieces of monocrystalline silicon photovoltaic panels with a size of 1924×1038×35mm photovoltaic panels.

During the day, photovoltaic modules generate electricity, and the controller and inverter convert direct current into alternating current for load use. The system gives priority to supplying electric energy to the load. When the electric energy generated by the photovoltaic is greater than the power of the load, the excess electric energy will charge the battery pack through the charge and discharge controller; when the light is weak or at night, the photovoltaic module does not generate electricity, and the battery pack passes through the inverter control integrated machine. The electric energy stored in the battery is converted into alternating current for the load.

Summary

Modular photovoltaic technology is applied to the office area and living area of the project department at the construction site of Building 4~6 in Pingshan New Energy Automobile Industrial Park, Shenzhen. A total of 49 groups are arranged in the 2A+B group (see Figure 5), equipped with 8 inverters The total installed capacity is 421.89kW, the average annual power generation is 427,000 kWh, the carbon emission is 0.3748kgCOz/kWh, and the annual carbon reduction of the project department is 160tC02.

Modular photovoltaic technology can effectively reduce carbon emissions on the construction site, making up for the neglect of carbon emission reduction in the initial construction stage of the building. Modularization, standardization, integration, and turnover can greatly reduce the waste of building materials, improve use efficiency, and reduce carbon emissions. The field application of modular photovoltaic technology in the new energy project department will eventually achieve a consumption rate of more than 90% of distributed clean energy in the building, more than 90% of the satisfaction of service objects, and reduce the carbon emission of the project department by more than 20% every year. In addition to reducing the carbon emissions of the overall building energy system of the project department, BIPV also provides a reference technical route for public buildings in different regions and under different climatic conditions to achieve carbon neutrality goals. Carrying out relevant research in this field in time and seizing this rare opportunity may make our country take the lead and lead in this revolutionary change.

Post time: 17-07-23