Amidst the continued growth in demand for modular buildings and temporary facilities, prefabricated container houses have been widely adopted in construction sites, mining camps, energy camps, emergency housing, and overseas engineering camps.

For purchasers, in addition to price, delivery time, and configuration, “lifespan” remains a core indicator for evaluating return on investment.

I. What is the standard design service life of flat pack containers?

According to industry standards, the design service life of a high-quality flat-pack container house is typically 15–25 years. Under reasonable maintenance conditions, some projects can be used stably for more than 30 years.

|

Application Type |

Typical Service Life |

| Temporary Construction Offices / Workers’ Dormitories | 10–15 years |

| Long-term Infrastructure and Energy Camps | 15–25 years |

| Semi-permanent Commercial Building/ Public Buildings | 20–30 years |

| High-Standard Custom Projects | ≥30 years |

It is important to emphasize that: Service life ≠ mandatory scrapping time

but refers to the economically reasonable service life under the premise of meeting safety, structural stability, and functional requirements.

II. Five Core Factors Determining the Service Life of Chinese Flat Pack Houses

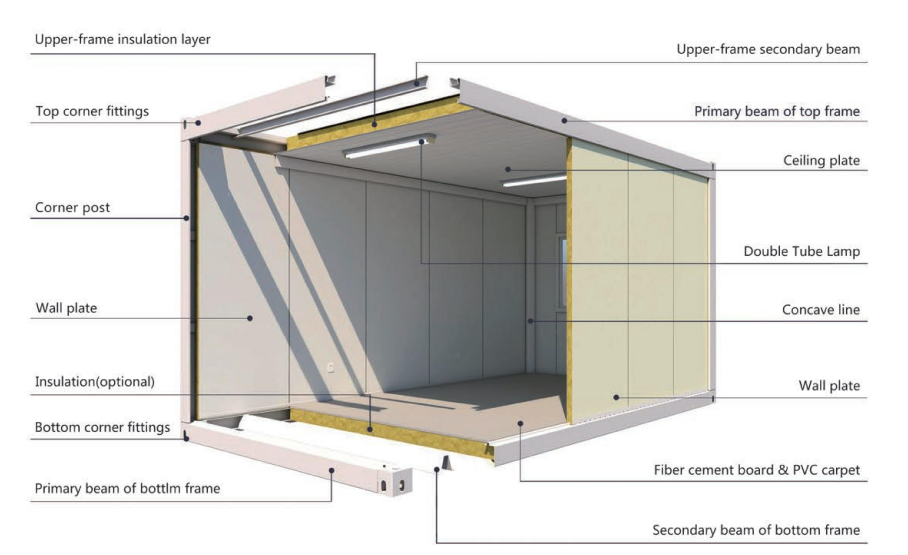

Main Steel Structure System (Determines Maximum Lifespan)

The “skeleton” of a flat pack container determines its maximum lifespan.

Key indicators include:

Steel grade (Q235B / Q355)

Steel section thickness (columns, top beams, bottom beams)

Welding method (full penetration vs. spot welding)

Structural corrosion protection system

Engineering-grade standard recommendations:

Column thickness ≥2.5–3.0mm

Main beam thickness ≥3.0mm

Key nodes should use integral welding + reinforcing plate design

Under the premise that the structure meets the standards, the theoretical lifespan of the steel structure itself can reach 30-50 years.

Corrosion Protection and Surface Treatment Processes

Corrosion is the number one killer that shortens service life.

Common Corrosion Protection Levels Comparison:

|

Corrosion Protection Method |

Applicable Service Life |

Applicable Environment |

| Ordinary Spray Painting | 5–8 years | Dry Inland |

| Epoxy Primer + Topcoat | 10–15 years | General Outdoor |

| Hot-Dip Galvanized Structure | 20–30 years | Coastal / High Humidity |

| Zinc Plating + Anti-Corrosion Coating | 25–30+ years | Extreme Environments |

For labor camp projects in mining areas, coastal areas, deserts, high humidity, or cold regions, hot-dip galvanizing or anti-corrosion systems are almost a “must-have.”

Enclosure System and Material Configuration

Although the enclosure system does not directly bear weight, it immediately affects comfort and long-term usability.

Core Components:

Wall sandwich panels (rock wool / PU / PIR)

Roof waterproofing structure

Door and window sealing system

Ground load-bearing and moisture-proof layer

High-quality projects typically use:

≥50 mm fire-resistant rock wool or PU board

Double-layer waterproof roof design

Aluminum alloy or thermally broken window frames

With proper configuration, the collapsible building envelope system can last 10–15 years, and its overall lifespan can be extended through replacement.

III. Prefabricated Container Houses vs. Traditional Container Houses: Lifespan Differences Analysis

|

Comparison Dimensions |

Prefabricated Container Houses |

Modified Container Houses |

| Structural Design | Architectural Grade | Transportation Grade |

| Anti-corrosion System | Customizable | Original Container as Main |

| Lifespan | 15–30 years | 10–15 years |

| Space Comfort | High | Average |

| Maintenance Costs | Controllable | High in the long run |

Prefabricated containers are not a “lightweight compromise” but rather a modular system specifically designed for building usage scenarios.

IV. How to Extend the Service Life of Prefabricated Container Houses?

From the procurement stage, the following points should be considered:

Clearly define the project’s service life target (10 years / 20 years / 30 years)

Match the corrosion resistance level, not just the price.

Request structural calculations and corrosion resistance specifications.

Choose flat pack container house manufacturers with long-term project experience.

Reserve space for future upgrades and maintenance.

V. Service Life: A Reflection of Systems Engineering Capabilities

The service life of prefabricated container houses is never a simple number but rather a comprehensive reflection of structural design, material selection, manufacturing processes, and project management capabilities.

With a high-standard design and proper maintenance, container houses in China can indeed become modular building solutions with stable use for 20–30 years.

Selecting the appropriate technological path is far more crucial for projects seeking long-term value than merely cutting initial costs.

Post time: 26-01-26