A Procurement Manager’s Perspective on Flat Pack Container Camps

For procurement managers in the wind power sector, the biggest hurdle often isn’t the turbines or the power lines; it’s the people.

Wind farms are often in isolated, inhospitable areas where infrastructure is scarce. Ensuring safe, compliant, and quickly deployable prefab building for engineers, technicians, and construction crews is paramount.

Lately, prefabricated container camps, particularly flat-pack porta-camps, have emerged as the go-to solution for wind power projects.

|

|

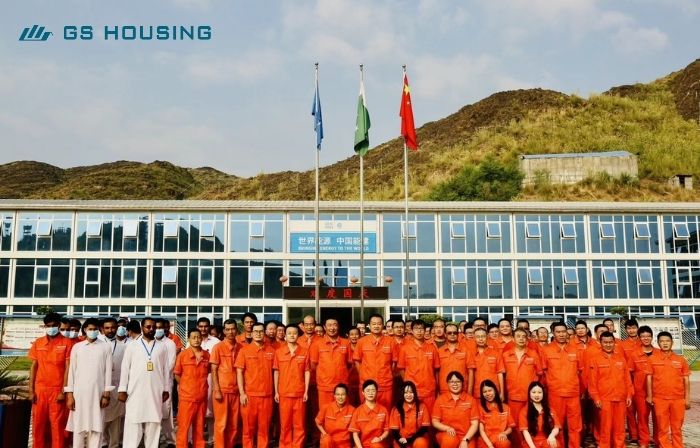

The Wind Power Container Camp Project: A Real-World Look in Pakistan

Wind energy initiatives often grapple with a host of logistical hurdles. These include:

Difficult-to-reach sites, often with inadequate road infrastructure, pose significant logistical challenges.

Compressed construction timelines necessitate a fluctuating workforce.

The project faces challenging environmental conditions, including deserts, high altitudes, coastal winds, and frigid areas.

Although the occupancy is temporary, it continues for an extended period.

Strict HSE and ESG mandates are now standard for project owners.

Conventional on-site construction frequently proves sluggish, expensive, and fraught with uncertainty. Worker accommodation camps for wind energy projects, however, offer distinct advantages.

Why Opt for Sustainable Modular Camp Solutions?

From a procurement and cost-control perspective, flat-pack prefab camps strike a balance between speed, adaptability, and long-term value.

1. Rapid Deployment for Compressed Project Schedules

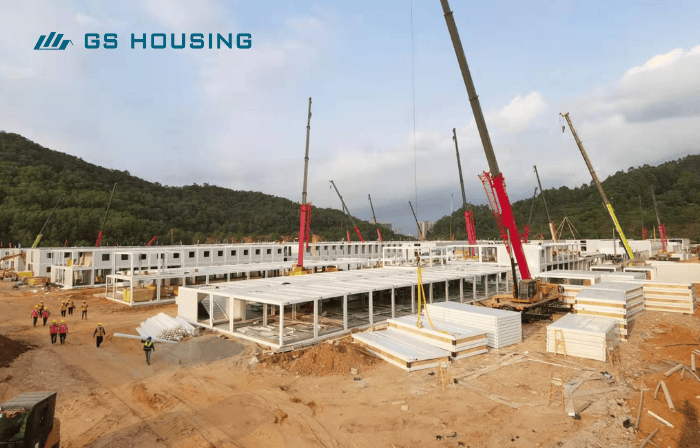

Wind power projects simply can’t afford setbacks. Flat-pack container units are built off-site, shipped in manageable packages, and quickly assembled on-site.

Minimal foundation needs

Swift on-site assembly with small teams

Scalable deployment that mirrors project phases

This feature allows reusable, modular container buildings to be operational weeks sooner than traditional structures.

|

|

2. Streamlined Logistics and Transportation Expenses

Wind farms situated far from urban centers frequently necessitate lengthy transportation, whether by truck or ship. Flat-pack modular camps offer a significant advantage in this regard:

Multiple modular prefab units can be packed into a single shipping container.

This approach reduces the freight cost per square meter.

It also simplifies access to remote or restricted locations.

For extensive labor accommodation camps within the wind power sector, the potential for logistics savings is considerable.

|

|

3. Adaptable Worker Camp Design

The need for manpower varies throughout the different phases of a project. Modular prefab camps provide the flexibility to easily configure:

Worker accommodation blocks, site offices and meeting rooms, modular canteens, kitchens, and dining halls, as well as sanitary modules and laundry facilities.

These modular units can be added, moved, or removed without causing disruptions to ongoing operations.

|

|

|

|

|

|

Total cost of ownership is a crucial factor.

While the initial cost per unit is important, procurement decisions are based on the total cost of ownership:

A shorter construction period reduces indirect costs.

Reusability across multiple projects is a benefit.

Dismantling and site restoration costs are lower.

Quality and compliance are more predictable.

Flat-pack container camps consistently offer better long-term value than traditional temporary buildings.

The modular container camp system has become the standard for wind power projects in remote and challenging environments, rather than just an alternative.

Post time: 30-12-25