Providing Efficient, Safe, and Sustainable Worker Accommodation and Office Solutions for Oil and Gas Projects

I. Introduction of the oil industry

The oil industry is a typical high-investment, high-risk industry. It’s exploration and development projects are typically located in geographically remote areas with harsh natural environments and poor infrastructure. Whether in the deserts of the Middle East, the grasslands of Africa, or the cold plateaus of Central Asia, oil companies need to provide reliable, safe, and comfortable living and working environments for a large number of on-site personnel.

Traditional man camp buildings, while meeting long-term use requirements, have significant shortcomings in terms of construction cycle, transportation difficulty, environmental adaptability, and cost control.Prefabricated container houses, as a new type of modular building, are gradually becoming an ideal choice for oilfield camp construction due to their advantages, such as rapid installation, flexible combination, and recyclability.

II. Overview of Prefab Container Houses

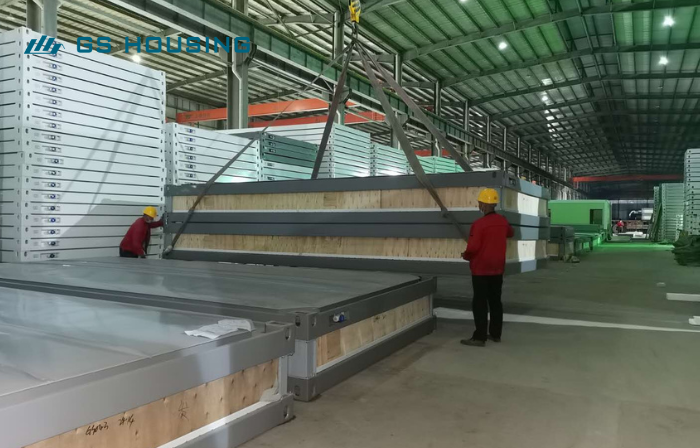

Prefabricated containers are mobile buildings prefabricated using standard shipping container dimensions, with steel structural frames and composite insulation wall materials. Each modular unit is manufactured, wired, and assembled in the factory. After transportation to the site, it only requires simple assembly and connection for immediate use.Its standardised modules can be freely combined to form various functional buildings such as staff dormitories, container office buildings, modular canteens, medical areas, and bathing areas. Due to its rapid installation, repeated disassembly and reassembly, and convenient transportation, modular prefab houses are particularly suitable for cyclical and highly mobile oilfield camp development and construction projects.

|

|

III. Characteristics and Challenges of Oilfield Labour Camp Construction

Staff camp construction in the oil industry differs significantly from ordinary construction projects.The main challenges include:

Complex environment: Oil fields are typically located in deserts or regions with harsh climates such as high temperatures, cold, or humidity, which places extremely high demands on the durability, corrosion resistance, and wind and sand resistance of prefabricated building materials.

Remote Geographic Location: Transportation to oil and gas field development areas is inconvenient, making the transportation of traditional prefab building materials difficult and costly.

Tight Schedule: The exploration, drilling, and extraction phases of oil projects require the establishment of complete production and worker living camps within a short period.

High Project Mobility: Oilfield development is phased; after one area is completed, relocation to a new drilling area is often necessary. Therefore, modular camp buildings should be easy to relocate and reuse.

The growing demand for quality of life: Modern oil companies are increasingly valuing the work-life experience of their employees, requiring comfortable, safe, and fully functional employee dormitories and supporting facilities.

Therefore,prefabricated houses have emerged as an efficient solution to the aforementioned challenges.

IV.Main Applications of Mobile Houses in Oilfield Man Camps

Oilfield prefab camps typically consist of several functional zones, including portable labor accommodation, prefab offices, public areas, living support areas, and modular medical clinics. A transportable house can meet almost all the construction needs of these areas.

1.Employee Dormitory (Living Quarters)

Prefabricated container dormitories are the most widely used housing in oilfield camps.

Flexible Configuration: Can be configured as single, double, or multi-person rooms. Each modular room is equipped with a bed, a wardrobe, AC, lighting, electrical outlets, and a private bathroom according to the project’s demand.

Comfortable and Durable: The walls of the container house are constructed with rock wool sandwich panels, offering excellent thermal insulation, fire resistance, and noise reduction.

Stackable Design: Prefabricated modules can be stacked to form two-story or three-story dormitory buildings, saving floor space.

2.Modular Office & Control Building

The management and technical teams require an independent portable office and meeting room.

Flexible Internal Layout: Can be configured as individual offices, meeting rooms, a document room, or a rest area.

Fully Equipped: Equipped with network cabling, AC, power systems, and lighting.

System Integration Capable: Can accommodate monitoring, communication, and data center equipment, supporting on-site management.

3. Prefabricated Canteen & Kitchen

To meet the daily dining needs of on-site personnel, the container camp canteen should have the following characteristics:

Complete Functionality: Includes a food preparation area, cooking area, dishwashing area, and dining area.

Hygiene and Safety: The interior uses fire-resistant and oil-resistant materials for easy cleaning.

Easy Expansion: Stackable prefabricated modules can be quickly added to accommodate changes in the number of personnel.

4.Sanitary & Medical Clinics

Oilfield work environments are highly hazardous, making medical and sanitation facilities an essential component of the oil man camp.

The sanitation room includes shower rooms, toilets, and laundry rooms, which can be used individually or centrally.

The modular medical clinic includes a first-aid room, pharmacy, and isolation room, providing workers with daily and emergency medical services.

Integrated Water and Electricity Systems: All container modules are pre-installed with water supply, drainage, and power interfaces for quick connection to the labor camp‘s main system.

5. Public & Recreation Building

In long-term accommodation environments, employee mental health and social activities are equally important.

Flat-packed housing can be converted into a gym, recreation room, library, worship room, shop, etc.

These facilities effectively improve the quality of life at the oil and gas camp and employee satisfaction.

6.Special Purpose Building

Customization is also available to meet specific oil field camp needs:

Control Cabin: Used for real-time monitoring of equipment operation and data analysis.

Workshop Container: Provides space for equipment repair and spare parts storage.

Storage Container: Safely stores supplies and fuel.

V. Role and Advantages of Modular Camp for Oilfield

1. Rapid Construction, Shortened Construction Period

Fabricated houses are manufactured in the factory and assembled on-site.

Ninety percent of the construction work has been completed in the factory. It can be used immediately after on-site hoisting and connection.

Compared with traditional buildings, this saves approximately 70% of the construction time.

2. Flexible Combination, Scalable Modules

Module units can be flexibly added or removed according to project progress and personnel numbers to meet staff camp needs at different stages.

The modular structure also supports multiple disassembly and relocation, resulting in high reusability.

3.Excellent adaptability.

The robust structure of GS Housing porta cabin is corrosion-resistant, moisture-proof, and fire-resistant, capable of withstanding extreme weather conditions such as strong winds, torrential rain, and sandstorms, with a service life exceeding 20 years.

Suitable for various geographical environments such as deserts, plateaus, and coastal areas.

4. Energy-saving and environmentally friendly, sustainable use

Wall insulation design reduces energy consumption and air conditioning load.

Easy to assemble and disassemble, recyclable, and reduces construction waste.

Optional green solutions such as solar energy systems and rainwater harvesting systems are available.

5.Controllable costs and convenient maintenance

Factory production increases standardization, reducing labor and material waste; installation and maintenance are simple, resulting in low post-management costs.

6. Improved living conditions and increased work efficiency

A comfortable living and working environment effectively enhances employees’ sense of security and work enthusiasm, indirectly promoting the efficient operation of man camp oil fields projects.

VI. The future trends and development directions of modular buildings

With the increasing emphasis on sustainable development in the oil and gas industry, prefabricated container houses will present the following development trends in the construction of oilfield barracks:

Integrated design: In the future, modules will integrate systems such as water, electricity, HVAC, communication, and security monitoring to form intelligent modular camp buildings.

Green and Energy-Saving: Utilizing solar panels, water-saving devices, and environmentally friendly materials to achieve low-carbon operation.

Personalization and Aesthetics: While meeting functional requirements, greater emphasis will be placed on exterior design and interior comfort.

International Standards: More modular camp projects for oilfield workers will adopt modular cabin that comply with ISO and petroleum industry standards for cross-border transportation and assembly.

|

|

VII. Conclusion

The emergence of detachable prefabricated houses provides a new, efficient, flexible, economical, and sustainable solution for mancamp housing construction in the oil industry.

The modular house not only solves the problems of long construction periods, difficult transportation, and high maintenance costs in remote areas, but also achieves standardization and modernization of portable camp construction through a modular concept.

In future global oil and gas development, detachable container houses will continue to play an important role, providing oil workers with a safe and comfortable living environment, saving costs and improving efficiency for enterprises, and will become one of the core solutions for oilfield camp construction.

|

|

Post time: 14-11-25